The selection of AGV lithium battery has a great impact on the overall AGV. It will directly affect the AGV's continuous navigation capability and the stability of the AGV. The continuous working cycle and charging time of the AGV also directly determine the production efficiency of the AGV. The management and control of AGV lithium batteries can ensure the good and stable performance of the AGV's onboard power battery and extend the service life of the AGV lithium battery. Below, Jinchi editor will explain to you what AGV lithium battery is:

Raw materials

Previously, domestic AGV lithium batteries generally used nickel-cadmium batteries and lead-acid batteries. Because these batteries are heavy, large, and contain heavy metals and other defects. Now many AGV manufacturers use AGV lithium batteries with small size, light weight, good high and low temperature rate discharge performance, long life, environmental protection, and simple maintenance.

AGV lithium battery is 1.5 times the volume of nickel-cadmium battery and 2 times the density of nickel-cadmium battery with the same high capacity; the average operating voltage of AGV lithium battery is 3.6V, which is 3 times that of nickel-cadmium battery and nickel-metal hydride battery. It has the characteristics of wide operating temperature, long charge and discharge life, stable operation, etc.

Steps

AGV lithium battery automatic charging system solution:

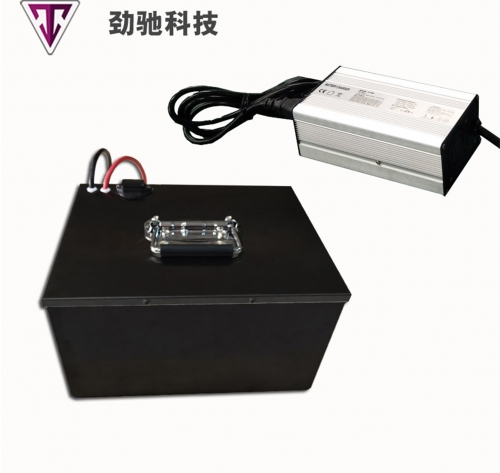

The battery used in the AGV car is a 24V/60AH lithium iron phosphate battery, with a normal charging current of 20A, a fast charging current of 100A, and a charging voltage of 28.8V. Charging method: automatic charging. The charging system should consist of three parts: the lithium battery pack remaining capacity (SOC) detection device, namely the ampere-hour meter, the automatic charger and the charging automatic docking interface.

1. Ampere-hour meter The ampere-hour meter is an instrument for measuring the SOC and voltage of the lithium battery pack. It should be installed on the AGV car and display the SOC value and voltage value of the battery pack in a timely manner. When the remaining capacity of the battery pack reaches 20 of the rated capacity or the battery pack voltage is lower than 20V, the ampere-hour meter should send an alarm signal to notify the AGV car background monitoring that the car should go to the charging position for charging; the signal form is a dry contact signal or a 485 communication signal.

2. The intelligent charging device of the charger AGV uses a programmable controller as the main control unit and a 7-inch color LCD touch screen as the human-machine exchange platform; the main circuit uses a high-frequency switching power supply circuit, which has the characteristics of light weight, small size, high efficiency, high voltage and current stability precision. The whole set of equipment is easy to operate, reliable, fully protected, and highly automated. Provide 485 communication interface and dry contact signals (charging, standby, full and fault) for the background monitoring of the AGV, and exchange data and working status with the host computer in a timely manner.

1) AC input voltage: AC220V±10 /50Hz2) DC output voltage: DC 0-30V3) DC output current: DC 10-100A4) Noise: ≤55dB (1 meter away with the front and rear doors closed)5) Cooling method: air cooling6) Dimensions: height 900mm×width 600mm×thickness 400mm7) Weight: about 40kg8) Installation method: ground

3. Interface Battery charging interface: There are single-pole, bipolar, three-level, 20A, 60A, 80A, 100A, 200A and other specifications. It can be used for lithium batteries, lead-acid batteries, nickel-hydrogen batteries, nickel-cadmium batteries and other batteries. It can also be used in the online charging system of AGV navigation transport vehicles. The products are widely used in charging systems in the fields of power, railways, communications, logistics automation, national defense, petrochemicals, metallurgy, coal mining, etc., and can completely replace imported products.